What Did You Say?

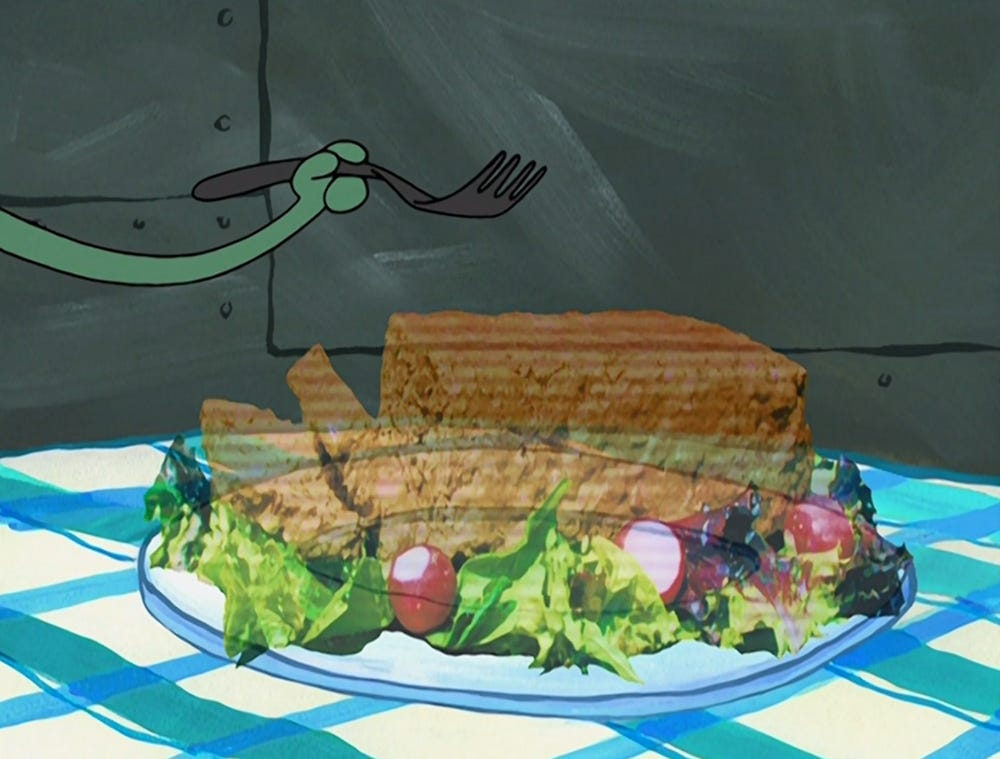

Yep, holographic meatloaf. You might recall, in an excellent episode of Spongebob Squarepants, Plankton comes home to his computer wife Karen and a tasty plate of his favorite dinner, holographic meatloaf. He excitedly drives his Plankton-sized fork into an odd, ghostly rendition of homemade meatloaf, a futuristic “whoosh” sounding each time he picks up a bite—food made from air.

Other mainstream entertainment has featured futuristic food made from air, too. Fans of The Hitchhiker’s Guide to the Galaxy series might remember the Nutrimatic Drink Dispenser, a device that produces a customized drink based on your neurological signals. The beloved FLDSMDFR (pronounced phonetically) from Cloudy with a Chance of Meatballs can produce complex meals like cheeseburgers, donuts, spaghetti, and of course meatballs from clouds. In the Star Trek universe, replicators synthesize complete meals just from energy. Even the Jetsons eat meals condensed into tiny pills or instantly produced out of thin air, reimagining the future of food culture with their Dial-a-Meal and food-o-matic systems.

Now, we might get our fair share of Plankton’s holographic meatloaf. Maybe you’ve seen an article like this one in the past few months, featuring companies that are growing edible protein from air, like Air Protein (aptly named, I might add) and Solar Foods.

Value Proposition

Why bother trying to make protein from air? You might already know, intuitively; this fermentation—the chemical breakdown of air by microbes—requires very little land, and we can make protein from air anywhere with a fermentation facility (or the potential to build one). Conventional agriculture requires arable, grazable land, limiting its capacity for protein production. With fermented protein, there is more available land to produce food, and fermentation facilities can run on renewable energy, reducing environmental impact even further. Air protein fermentation is also a carbon negative process, meaning it removes carbon from the atmosphere, helping to mitigate the effects of climate change.

Science

How do people make air from protein? Let’s break it down (pun fully intended).

Although we may forget in our everyday lives, air does actually contain “stuff.” Air is full of oxygen, carbon dioxide, water vapor, and nitrogen—everything that microbes need to survive! As microbes digest these gases, they grow and grow and grow, until it’s time to harvest, purify, and dry the protein.

The inspiration for microbial protein from air hails from NASA; the original pitch included using carbon dioxide that the astronauts exhaled for biomass fermentation, creating a completely circular process for protein production. As astronauts breathed in oxygen and exhaled carbon dioxide, the carbon dioxide would be fed to microbes to produce biomass, adding another available source of protein in space. Though, at the time, the major barrier was psychological; astronauts didn’t want to eat food like that.

But times are changing, and these novel foods are back on our plates. Companies are utilizing novel branding strategies to change our perception of microbial protein. Take a look at some of Air Protein’s marketing tools found on their website:

To make protein from air, companies grow microbial cultures in bioreactors, or large, usually stainless steel, closed containers. Bioreactors allow scientists to precisely control growth conditions like temperature, the rate of nutrient flow, pH, and culture density. Scientists first clean the bioreactor (to prevent any unwanted growth) and load it with liquid nutrients, called broth. When the culture reaches a certain threshold of growth, they empty the contents of the bioreactor and separate the broth from the microbes, resulting in a paste-like mass of cells.

After the fermentation, they break open the cell membranes, also called lysis (pronounced lye-sis, rhymes with crisis), in order to access the proteins that are inside the cells. But there’s a lot of other stuff inside cells, too, so they have to separate the protein from the cell debris (mostly water, cell membrane remnants, DNA, and other small molecules) through purification steps. The extracted protein is then dried to create a flour that can be added to baked goods or turned into other functional foods spanning dairy, meat, and grains. Some companies even use this protein flour as a supplement in pet food or agricultural feed.

Closing

Let’s just take a moment and peruse the myriad of futuristic food featured in our favorite films.